Winter diesel fuel additives are used to increase the winter operability of distillate fuels. When properly used, CFPP additives change the shape and size of wax crystals, keeping them small in size so they can more easily pass-through fuel system filters at lower ambient temperatures than without these additives.

One caveat of the CFPP treatment is time. The longer a CFPP-treated fuel sits in a saddle tank at low temperatures, the more likely gravity will promote wax settling at the bottom of the tank.

Even though the treated wax crystals are small, they eventually settle to the bottom of a fuel tank, and the higher density of these wax crystals can overwhelm filters on startup (the fuel pick-up is normally at the bottom of the tank). When this happens, filter plugging will usually occur at a temperature higher than the reported CFPP temperature. This problem is easily solved if the right additive package combination is chosen.

The correct package should contain “WASA.”

A wax anti-settling additive (WASA) will disperse the treated wax so it stays suspended in the fuel and does not settle on the bottom of the tank after a long cold soak. The CFPP temperature is now more reliable since the suspended wax does not agglomerate on the bottom of the tank and plug the fuel filter on vehicle startup. Wax crystals stay small enough to pass through the filter thanks to the action of the CFPP additive; at the same time, the WASA keeps the wax suspended, and the mixture is homogeneous, so the wax can’t collect at the bottom of the tank.

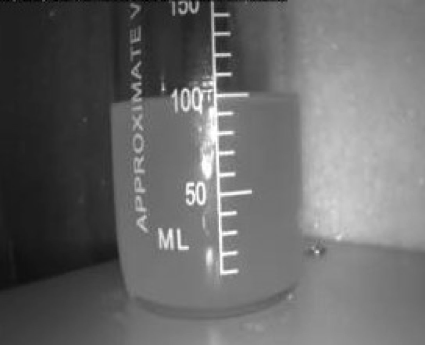

To evaluate the wax settling performance of cold flow improver additives (a generic term for additives with and without WASA), a treated and untreated fuel sample is cooled to sub-zero temperatures. The sample sits undisturbed, and time-lapse photos are taken. The resulting images show the rate at which wax settles and visually indicate the reliability of the given additive at a selected treatment rate.

Notably, the additives tested here have significant differences in WASA performance. CFPP additives with higher levels of WASA additive visibly indicate the most reliable operability. Suppose you have a critical application, i.e., such as a state DOT bid or another requirement with a hard CFPP target to meet and penalties associated with non-attainment of the target CFPP. In that case, you should look for additive products that provide the best protection from settling. Your additive supplier can help you with that choice.

Wax Settling study: two fuel samples of the same fuel, all held at -15F for three days.

- Sample I: treated with CFPP additive at the manufacturer’s recommended dose of 1000 ppm.

- Sample ETP: treated with ETP Winter Additive with WASA at the recommended dose of 800 ppm.

- Both ETP and the competitor additives claim to have a WASA component.

Analysis:

- The competitor sample had to settle on the first day of the test with a high density of wax at the bottom of the sample. This intensified as more time was allotted for the test.

- The ETP sample had an even wax suspension for the length of the test and did not allow the wax to settle after three days.

Competitor I Sample: CFPP additive @ 1000 ppm, reported CFPP = -28F. Soak temperature -15F.

overwhelm/plug a filter.

ETP Winter Additive with WASA sample: CFPP additive @ 800 ppm, reported CFPP = -30F. Soak temperature -15F.

By: Stephen Boracchia – National Accounts Manager, sboracchia@teametp.com